Disc Washers

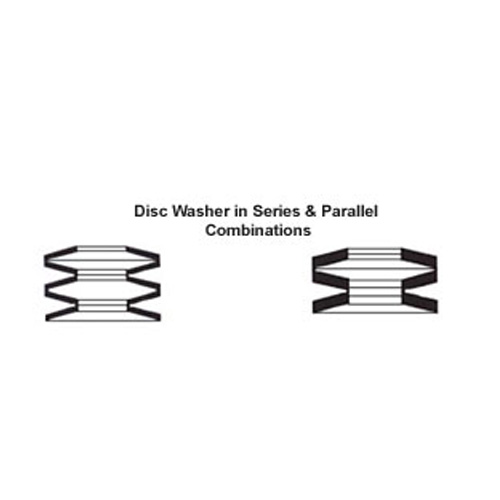

Disc Washers are conically formed angular Discs, which are loaded in the axial direction. Disc Washers offer a well-developed solution to many engineering problems. Through a unique combination of high force in a small space, Disc Washers can be used as single disc or arranged in stacks. A spring stack can consist of either single spring or parallel spring sets. Disc Washers are available with or without contact flats. Disc Washers and Belleville Washers are manufactured to DIN 2093 AND din 6796. We have computerized design programmed to assist our customers for their specified applications. Disc Washers are manufactured from imported 50CrV4 and EN42J material. Our Disc Washers are AUSTEMPERED. This method of heat treatment is particularly effective for springs, as it gives the maximum toughness and therefore considerable durability.

Disc Washers

Advantages of Disc Washers

- No Deformation or Fatigue under normal loads.

- High Energy Storage Capacity.

- Long Service Life.

- Stock keeping is minimized as the individual spring sizes can be combined universally.

- Space Saving.

- Largely Self-damping, giving good shock absorption and energy dissipation.

- Efficient use of space and high spring force with small deflections.

- Adaptable to stacking in numerous configurations.

- Combination use as a modular spring element.

- Low Maintenance cost

- Greater Security